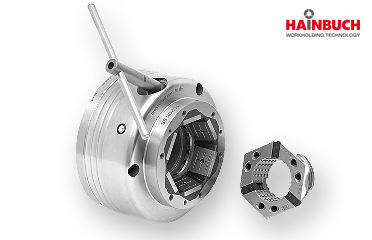

手動夾頭

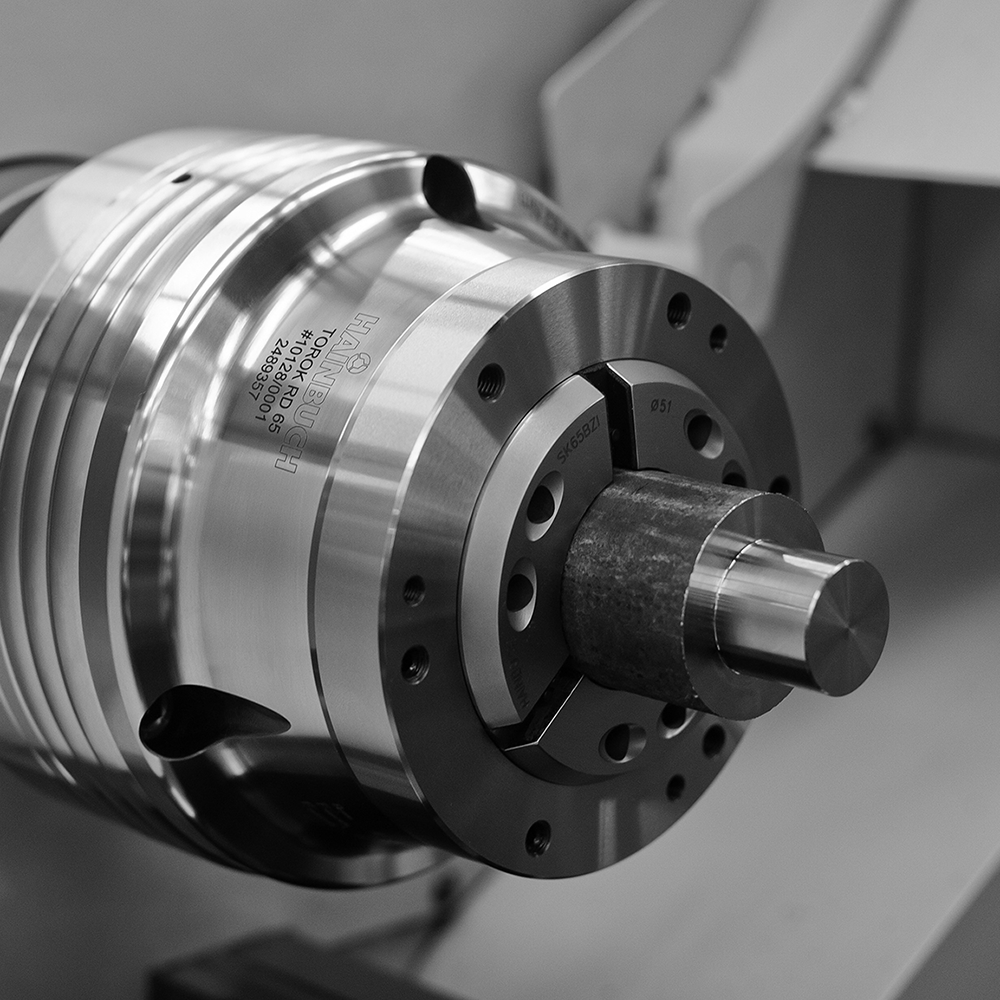

TOROK Chuck

無需油壓缸或其它動力

產品詳敘

Hainbuch TOROK Chuck

即使是手排跑車,一樣需要有優異馬力的操作敏捷

簡介:

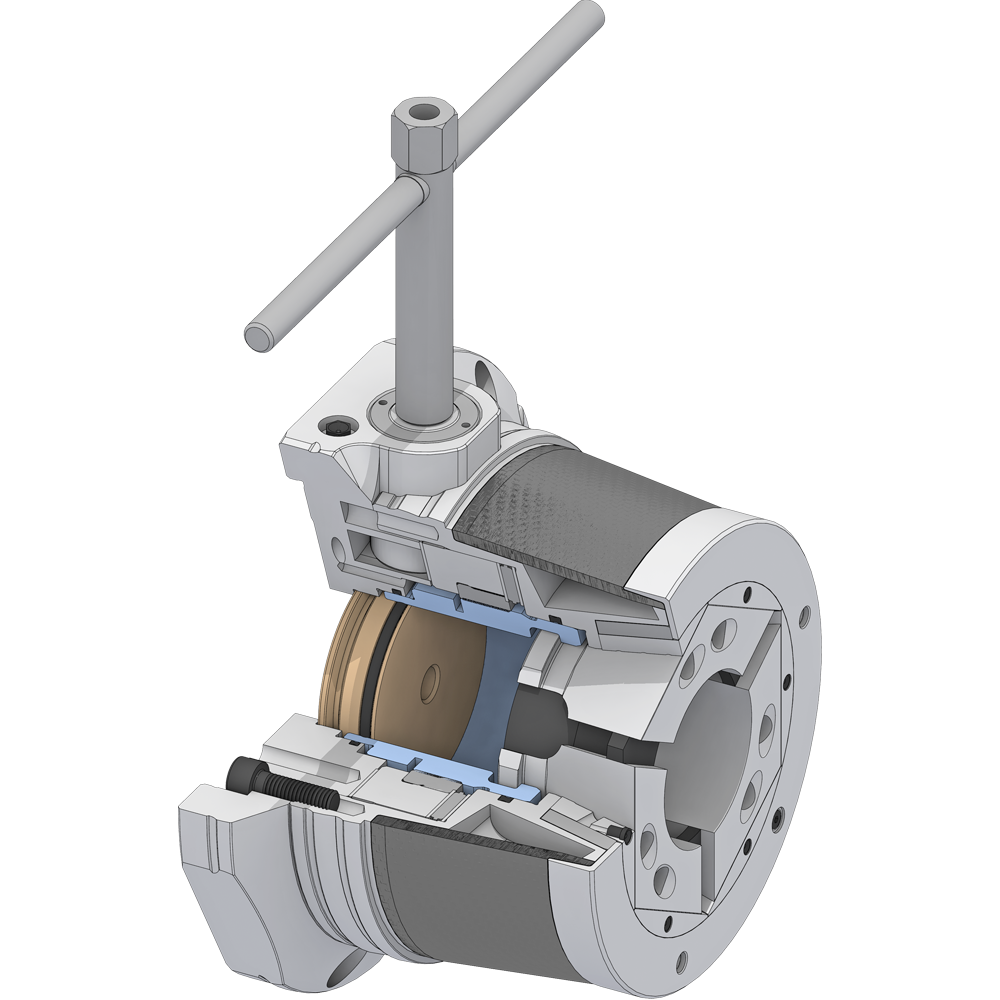

TOROK手動夾具王是迎合非動力夾持需求而設計,有很多機械需要精密夾持但沒有空壓或油壓單元可作驅動,因此手動夾頭極為適合類似的夾持需求,無論磨床、半自動機械,手動夾頭提供方便快速與重力夾持解決車切削需求,輕夾持可以達到的高同心度與重覆精度要求,提昇機械的生產效率。

標準規格:65型、100型(其它規格另詢)

適用於:圓筒、內孔磨床,車床,專用機,滾齒機、插齒機、教學使用車床。

亮點:

- 全包式夾持,使用標準夾固頭。

- 高剛性。

- 同心度與重複夾持精度高。

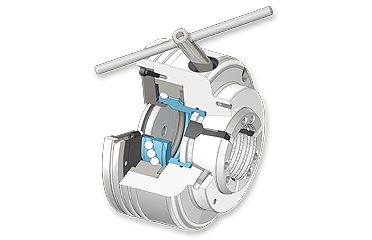

- 快速換模。

- 夾持力量高而且可以調整。

- 具備相同夾具王系統的優點。

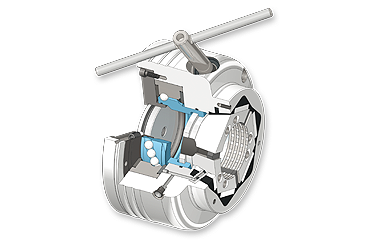

- 後拉式夾持,承靠止動器。

- 獨特夾持再加上額外的續夾能力。

- 更換不同夾固頭,同心度依然保持。

- 可高速運轉(有止動器時)且刀具壽命延長。

- 無須油壓缸或其它動力。

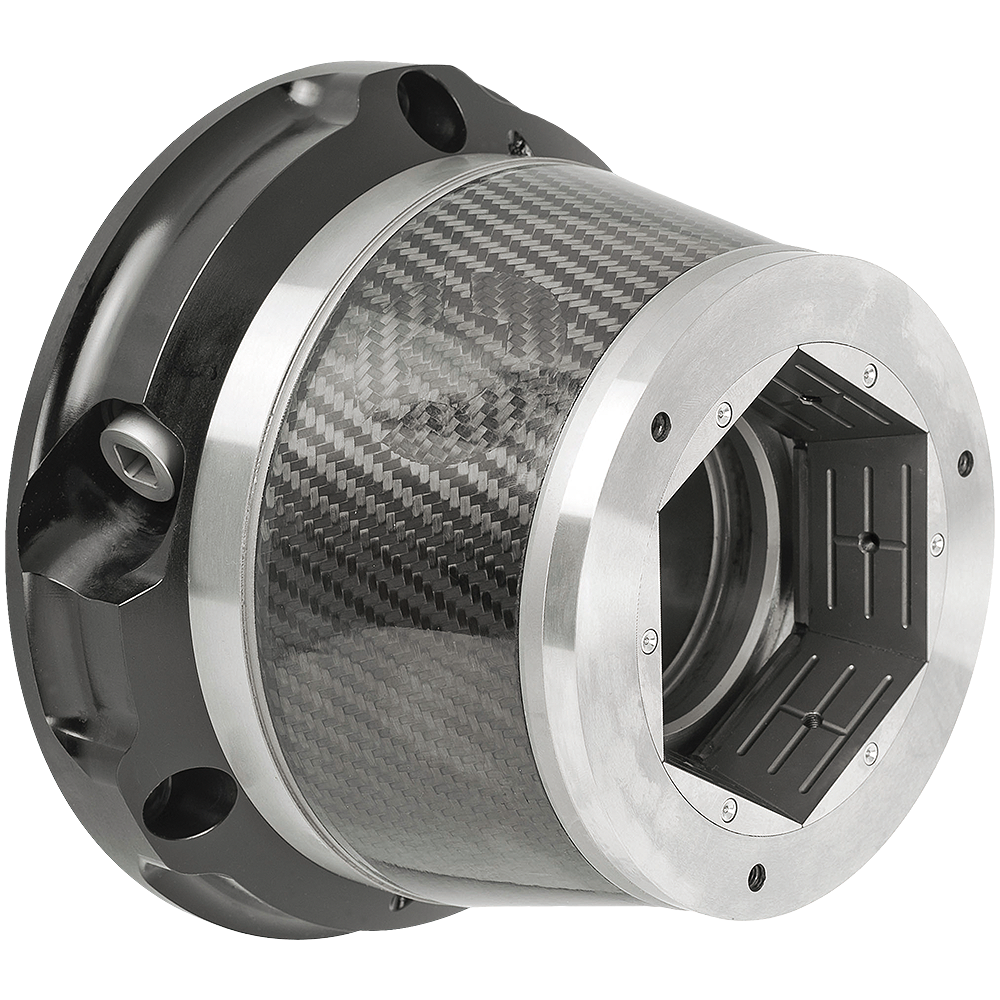

碳纖維輕量手動夾頭

- 比標準模式輕1/3

- 操作者友善的設置

- 減輕機器主軸的壓力

標準手動夾頭

用於不含油壓缸的機器

在磨床上使用時可安全、靈敏地夾持

快速轉換為 I.D.夾持或夾爪夾持[模組化系統]

影片:

Manual chuck TOROK

Clamps gently or forcefully

The TOROK manual actuated chuck is primarily used in prototyping machines without a clamping cylinder. Basically, it is implemented wherever users are reluctant to sacrifice the accustomed HAINBUCH quality when a clamping cylinder is not available.

Best of all:

Thanks to its easy manual actuation you can safely and delicately clamp in the customary manner when used on grinding machines. For example: With an optional base plate the TOROK can also quickly be converted for stationary use.

More clamping options in combination with clamping devices-adaptations

And in combination with our clamping device adaptation, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping possibilities are available to you. In the future you can also rely completely on the HAINBUCH modular system, even for your manual chuck.

Key advantages

- Sensitive manual clamping is possible

- Manual actuation – a clamping cylinder is not required

- Concentric precision < 0.01 mm possible

- Minimal inertia loss

- Standard flanges available with adjustable bolt, Camlock upon request