SE夾固頭

Clamping heads SE

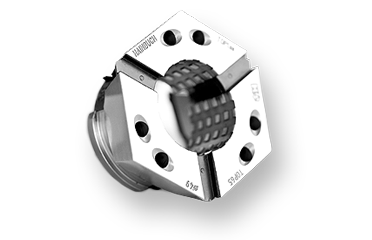

六角型夾固頭

產品詳敘

Hainbuch Clamping heads SE

SE 六角型,夾持更完美

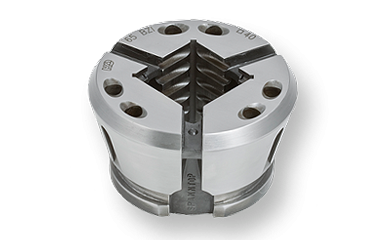

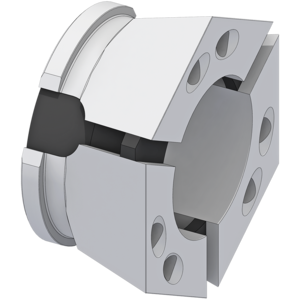

相較於SPANNTOP夾具, 在相同的油壓缸驅動力下, 六角型夾固頭可增加2 5 % 的夾持力, 而這都歸功於其金字塔狀的滑行表面。即使在夾持大公差工件時, 六角型夾固頭夾持面仍然可以完全貼合於托普勒司SPANNTOP夾頭本體上。此外, 六角型夾固頭的特殊外型較SPANNTOP系列更具防屑性。而其同心精度可達0.015mm(以65型SPANNTOP夾具來說)更是讓人難以置信。SPANNTOP系統更適用於粗胚材料、鑄鍛件, 但也適用於微粒非鐵金屬, 例如:銅。具各種優點的SPANNTOP夾具是您現代化生產策略與最新科技加工應用的理想幫手。

標準夾固頭樣式:

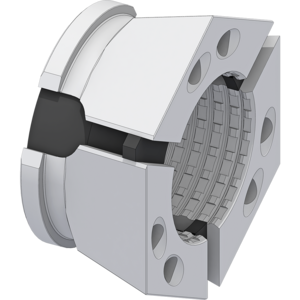

內孔研磨 六角 TOPlus夾固頭

內孔粗齒 六角 TOPlus夾固頭

優勢:

- 較SPANNTOP系統高25%的能量轉換。

- 夾具本體與夾固頭間無徑向移位,可有效防屑。

- 夾持面全面貼合,造就強而有力的穩固夾持力。

- 同心精度可達 < 0.015mm。

- 延長保養間隔期。

- 卓越的抗磨耗表現。

- 具備HAINBUCH夾具系列的特色:平行夾持、最佳的力能轉換、堅固、高夾持力,以及耐磨耗。

SE - hexagonal clamping geometry, holding power in perfection

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder acutating force that is used to actuate our SPANNTOP chucks.

Hexagonal Geometry

The pyramid arrangement of glide surfaces makes it possible. In addition, the hexagon geometry ensures that TOPlus is more resistant to contamination than former clamping head/chuck systems.

For some materials more suitable

Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of 0.015 mm!

Key advantages

- 25 % higher holding than clamping head RD [SPANNTOP]

- No radial displacement between clamping head and chuck body, therefore it is resistant to contamination

- Unequalled rigidity due to full-surface contact of the clamping segments

- Concentric precision < 0.015 mm possible

- Extended maintenance intervals