10|2016 Schwanog Insertable Form tool Systems!

沖齒刀具

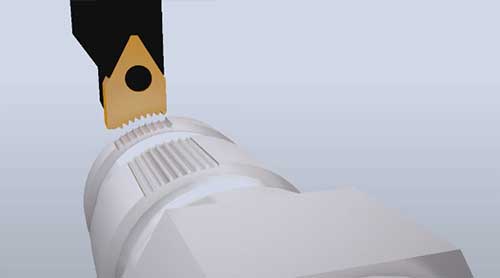

一般來說,有兩種方式可以在CNC車床上製作鍵槽(keyway)或排齒(spine)。

一是使用主軸或刀塔,二是使用沖齒刀座(broaching head)。

使用沖齒刀座的優點是對車床的機械衝擊小,而且速度上優於主軸或刀塔。

沖齒刀座市場上有不同的生產商,例如:Benz、EWS、Schwarzer、WTO、heimatec、ESA等

但不管哪家的沖齒刀座,schwanog都能提供相配的沖齒刀具。

配合應用schwanog能提供鎢鋼或HSS刀具。

影片:

重點摘錄:

- 沖齒刀座對車床的機械衝擊小

- 顯著的加工時間效益

- schwanog能提供與市場上大多數沖齒刀座配合的刀具

- 視應用schwanog能提供鎢鋼或HSS刀具

<翻譯者:Echo>

BROACHING TOOLS

FOR ALL COMMON BROACHING HEADS!

Generally, there are two potential ways of broaching keyways and splines on CNC lathes:

One is using a spindle or turret, the other a special broaching head.

Broaching heads have the advantage of low mechanical impact on the lathe and operate

much faster than spindles or turrets. Broaching heads are offered by different manufacturers

such as Benz, EWS, Schwarzer, WTO, Heimatec, ESA, etc. – but they all share one thing in

common:

Schwanog offers highly efficient broaching tools for almost all broaching heads. The

broaching tools can be made available in carbide or HSS depending on the application.

Facts:

- Broaching heads have a low mechanical impact on the lathes

- Significant time saving

- Schwanog broaching tools are available for almost all broaching heads

- Broaching tools are available in carbide and HSS