.png)

在傳動頂針中使用可移動中心銷進行車削

FSB/SB 型傳動頂針由尾座推力驅動

工件透過可移動的中心銷進行中心夾持

這樣可以調整不同的中心位置,從而確保工件端面具有恆定的基準點

最大跳動偏差約為 0.015-0.02mm

為了最大限度地提高扭力傳遞效率,應根據所使用的驅動銷/驅動盤調整尾座力

Face drivers of type FSB/SB are power-operated by the thrust of the tailstock. Workpieces are clamped centrically using a movable center pin. This way, different centerings can be adjusted, thus ensuring a constant datum point at the end face of the workpieces.

The maximum run-out deviation amounts to approximately. 0.015-0.02 mm.

In order to maximize the torque transmission, the tailstock force should be adjusted to the drive pins/drive disks in use.

Our practiced design and consulting teams will be glad to assist you.

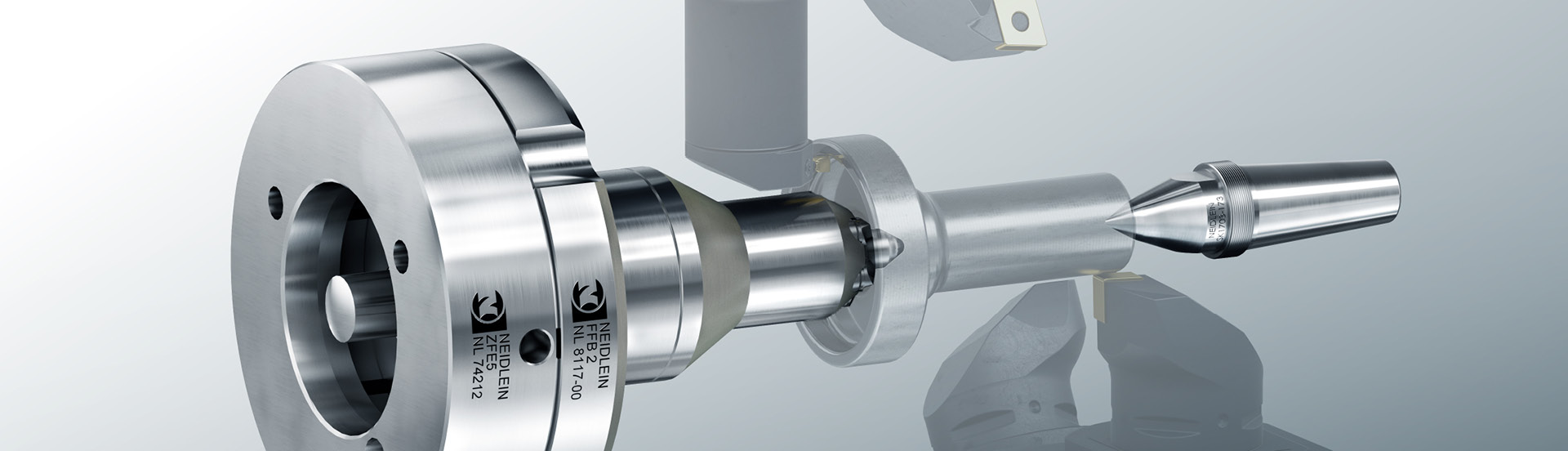

採用固定中心銷的傳動頂針進行車削,可提高精度

FFB/FFP 型傳動頂針由工具機主軸側和尾架側的動力驅動

工件透過固定中心銷進行中心夾持

這種操作方式可實現極高的真跳動精度

基準點位於工件中心

最大跳動偏差約為 0.002 - 0.01mm

為確保安全夾持,尾座力應比夾持油缸力高約 30%

為最大程度地提高扭力傳遞效率,應根據所使用的驅動銷/驅動盤調整尾座力

Face drivers of type FFB/FFP are power-operated on the side of the machine spindle as well as the side of the tailstock. The workpieces are clamped centrically by the fixed center pin. This operation results in high true run-out accuracy. The datum point is located in the center of the workpiece.

The maximum run-out deviation amounts to approximately. 0.002-0.01 mm.

The tailstock force should be approximately. 30% higher than the force of the clamping cylinder to ensure safe clamping.

In order to maximize the torque transmission, the tailstock force should be adjusted to the drive pins/drive disks in use.

Our practiced design and consulting teams will be glad to assist you.

在傳動頂針中使用固定中心銷進行車削

FFB/FFBH/FFP 型傳動頂針由工具機主軸側和尾架側的動力驅動

工件透過固定中心銷進行中心夾持

這種操作方式可實現極高的真跳動精度

基準點位於工件中心

FFB/FFBH/FFP 型驅動銷採用液壓驅動和補償,從而實現卓越的真跳動精度

最大跳動偏差約為 0.001-0.005mm

為確保安全夾持,尾座力應比夾持油缸力高約 30%

Face drivers of type FFB/FFBH/FFP are power-operated on the side of the machine spindle as well as the side of the tailstock. The workpieces are clamped centrically by the fixed center pin. This operation results in high true run-out accuracy. The datum point is located in the center of the workpiece.

Drive pins of type FFB/FFBH/FFP are hydraulically activated and compensated, thus achieving excellent true run-out accuracy.

The maximum run-out deviation amounts to approximately. 0.001-0.005 mm.

The tailstock force should be approximately. 30% higher than the force of the clamping cylinder to ensure safe clamping.

Our practiced design and consulting teams will be glad to assist you in finding a suitable clamping device as well as identifying the correct clamping thrust.

採用專為研磨而設計的夾持系統

FFBR/FBSR 型傳動頂針由工具機主軸側和尾座側的動力驅動

工件透過固定中心銷進行中心夾持

這種操作方式可實現極高的真跳動精度

基準點位於工件中心

透過裝卸工件,驅動銷會縮回

驅動銷採用「浮動」式設計,從而補償工件的垂直度和表面光潔度的變化

驅動銷透過懸掛的方式浮動,從而補償工件表面可能存在的不平整度

為了防止砂輪過衝,傳動頂針的錐形頭會向下傾斜

對於極高的跳動要求,可以透過調整螺絲來調整傳動頂針

最大跳動偏差約為 0.002-0.006mm

Face drivers of type FFBR/FBSR are power-operated on the side of the machine spindle as well as the side of the tailstock. The workpieces are clamped centrically by the fixed center pin. This operation results in high true run-out accuracy. The datum point is located in the center of the workpiece.

By loading and unloading the workpieces, the drive pins get retracted. The drive pins are „floatingly“, thus compensating for variations in workpiece, squareness, and surface finish. The drive pins are floating by suspended, thus compensating irregularities with regard to possible unevenness of the surface of the workpiece. For possible grinding wheel overrun, the face driver nose cone is cylindrically set down. For the highest run-out requirements, it´s possible to adjust the face driver by setting the screws. The maximum run-out deviation amounts to approximately. 0.002-0.006 mm. Our practiced design and consulting teams will be glad to assist you in finding a suitable clamping device as well as identifying the correct clamping thrust.

使用固定中心銷的傳動頂針進行研磨

FFB/FFBH 型傳動頂針由工具機主軸側和尾架側的動力驅動

工件透過固定中心銷進行中心夾持

這種操作方式可實現極高的真跳動精度

基準點位於工件中心

最大跳動偏差約為 0.002-0.01mm

為確保安全夾持,尾座力應比夾持油缸力高約 30%

Face drivers of type FFB/FFBH are power-operated on the side of the machine spindle as well as the side of the tailstock. The workpieces are clamped centrically by the fixed center pin. This operation results in high true run-out accuracy. The datum point is located in the center of the workpiece.

The maximum run-out deviation amounts to approximately. 0.002-0.01 mm.

The tailstock force should be approximately. 30% higher than the force of the clamping cylinder to ensure safe clamping.

Our practiced design and consulting teams will be glad to assist you in finding a suitable clamping device as well as identifying the correct clamping thrust.

銑削加工採用可移動中心銷和固定驅動頭

FDNC 型傳動頂針由尾座推力驅動

工件透過可移動的中心銷進行中心夾持這樣可以調整不同的中心位置,從而確保工件端面始終保持基準點不變

由於驅動頭固定,加工過程無反衝

可調節的彈簧式中心銷提供穩定性,並可承受高橫向推力

對於極高的跳動要求,可透過固定螺絲調整傳動頂針

最大跳動偏差約為 0.02mm

Face drivers of type FDNC are power-operated by the thrust of the tailstock. Workpieces are clamped centrically using a movable center pin. This way, different centerings can be adjusted, thus ensuring a constant datum point at the end face of the workpieces.

Machining is free from backlash due to fixed drive heads.

Adjustable, spring-loaded center pins provide stability and mounting for high transverse thrust.

For the highest run-out requirements, it´s possible to adjust the face driver by setting the screws.

The maximum run-out deviation amounts to approximately. 0.02 mm.

帶活動中心銷的銑削車削加工

FDNC 型傳動頂針由尾座推力驅動

工件透過可移動的中心銷進行中心夾持

這樣可以調整不同的中心位置,從而確保工件端面具有恆定的基準點

最大跳動偏差約為 0.02mm

為了最大限度地提高扭力傳遞效率,應根據所使用的驅動盤調整尾座力

Face drivers of type FDNC are power-operated by the thrust of the tailstock. Workpieces are clamped centrically using a movable center pin. This way, different centerings can be adjusted, thus ensuring a constant datum point at the end face of the workpieces.

The maximum run-out deviation amounts to approximately. 0.02 mm.

In order to maximize the torque transmission, the tailstock force should be adjusted to the implemented drive disks.

Our practiced design and consulting teams will be glad to assist you.

採用固定中心銷的傳動頂針進行車削加工,精度更高

FFBR/FBSR 型傳動頂針由工具機主軸側和尾座側的動力驅動

工件透過固定中心銷進行中心夾持

這種操作方式可實現極高的真跳動精度

基準點位於工件中心

最大跳動偏差約為 0.015mm

為確保安全夾持,尾座力應比夾持油缸力高約 30%

為最大程度地提高扭力傳遞效率,應根據所使用的驅動盤調整尾座力

我們經驗豐富的設計和諮詢團隊將竭誠為您提供協助

Face drivers of type FFBR/FBSR are power-operated on the side of the machine spindle as well as the side of the tailstock. The workpieces are clamped centrically by the fixed center pin. This operation results in high true run-out accuracy. The datum point is located in the center of the workpiece.

The maximum run-out deviation amounts to approximately. 0.015 mm.

The tailstock force should be approximately. 30% higher than the force of the clamping cylinder to ensure safe clamping.

In order to maximize the torque transmission, the tailstock force should be adjusted to the implemented drive disks.

Our practiced design and consulting teams will be glad to assist you.